The concern that has been around in the past few months is that many new electronic products are difficult to buy. This involves many related factors, such as COVID-19, economic environment, yield issues, etc., but there is a new argument for causing such a common chip shortage problem: insufficient investment in 200mm wafers.

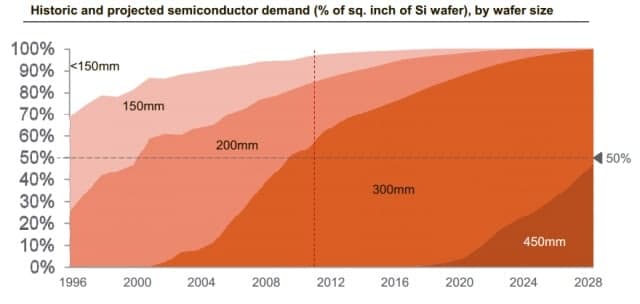

Today, the most advanced chips are manufactured on 300mm wafers. In the past few decades, manufacturers have been increasing the size of standard wafers from 100mm to 150mm to 200mm and 300mm. For a long time, people have believed that 300mm wafers are better than 200mm wafers because larger wafer sizes can reduce waste and usually increase the daily output of the foundry.

There are not many foundries dedicated to wafers of 150mm or smaller, but many foundries are still running 200mm production lines, TSMC, Samsung, and many second-tier foundries provide this node. GlobalFoundries, SMIC, UMC, Tower Semiconductor, and SkyWater all have 200mm production lines. Many IoT and 5G chips, as well as some analog chips, MEMS chips, and RF solutions, use 200mm wafers.

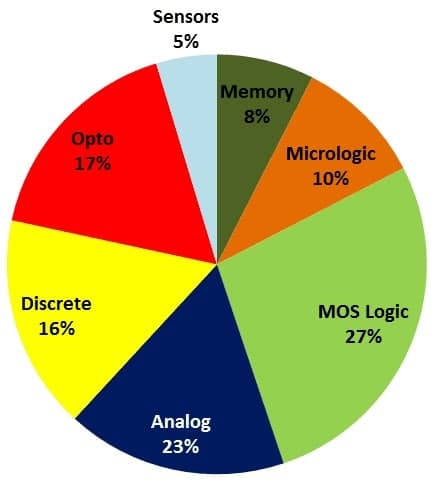

Image – Semico Research, 2018

It should be pointed out that products with relatively high attention, such as GPUs, CPUs, high-end cellular modem chips, and other similar products in desktops and mobile devices, are just a few chips in a device, and many of them are made through more mature technology and Lower cost manufacturing.

200mm wafers should have been gradually reduced with the use of 300mm wafers. During 2007-2014, this was indeed the case, but the trend has since reversed. The reason is that the 200mm production line is very mature and the cost is very low. In addition, many customers have not gained many benefits from migrating to larger wafers, and they want to use existing mature designs. This is also the reason why many IoT sensors and products use relatively mature nodes.

With the increase in demand for these products, before the new crown pandemic, the utilization rate of 200mm wafers in many factories was already high, and large foundries like TSMC have made slow progress in adding 200mm wafer capacity, making 200mm Wafers are becoming tight.

This old graph describes the proportion of 450mm wafers and also shows the changes in analysts’ estimates of 200mm wafer shipments. After 2015, the demand for 200mm began to grow again, and 450mm wafers have never been placed.

However, this does not mean that every foundry with a 200mm wafer production line has a high utilization rate. In some cases, it may take a lot of time and money for a company to migrate a new product design to a new fab. In other words, if a company designs chips for the production line of foundry A, it will be transferred to foundry B for production, which may bring huge costs.

The new crown pandemic has brought challenges to many industries, and the performance of the semiconductor industry is a highlight. The sales of home and office electronic products are a big plus, which means that there is additional demand for various chips, and of course, it also puts pressure on the supply chain.

“This year’s situation is very interesting. Not only has the demand for 200mm wafers increased, but the demand for the latest and special products has also increased significantly, including power supplies, CMOS image sensors, and RF radio frequency products.” Risto Puhakka, president of VLSI Research, told SemiEngineering. “If it is an analog chip IDM like TI and NXP, then 2020 will be difficult. The industrial, automotive, and power markets have been in a difficult situation affected by the pandemic. But at the same time, foundries are solving the problems in the consumer market. problem.”

The market situation is that the surge in demand for Wi-Fi and Bluetooth chips has caused a shortage of both chips. In addition, the demand for automotive electronics has grown faster than expected.

At this point, it is possible to answer to a certain extent the problem that some electronic products are difficult to buy at the beginning of the article. This is not just because the new COVID-19 pandemic has disrupted the supply chain.

At the same time, new laptops are needed to meet the needs of distance learning and office work, plus the highly anticipated new GPU release, Huawei’s advanced stocking, and now 200mm wafers The general shortage of chips is the reason for the general shortage of chips.

It is expected that by 2021, a monthly 200mm wafer capacity of 220,000 pieces (wpm) will be added, and the total global production capacity will exceed 6.4 million wpm by then.

(Source)