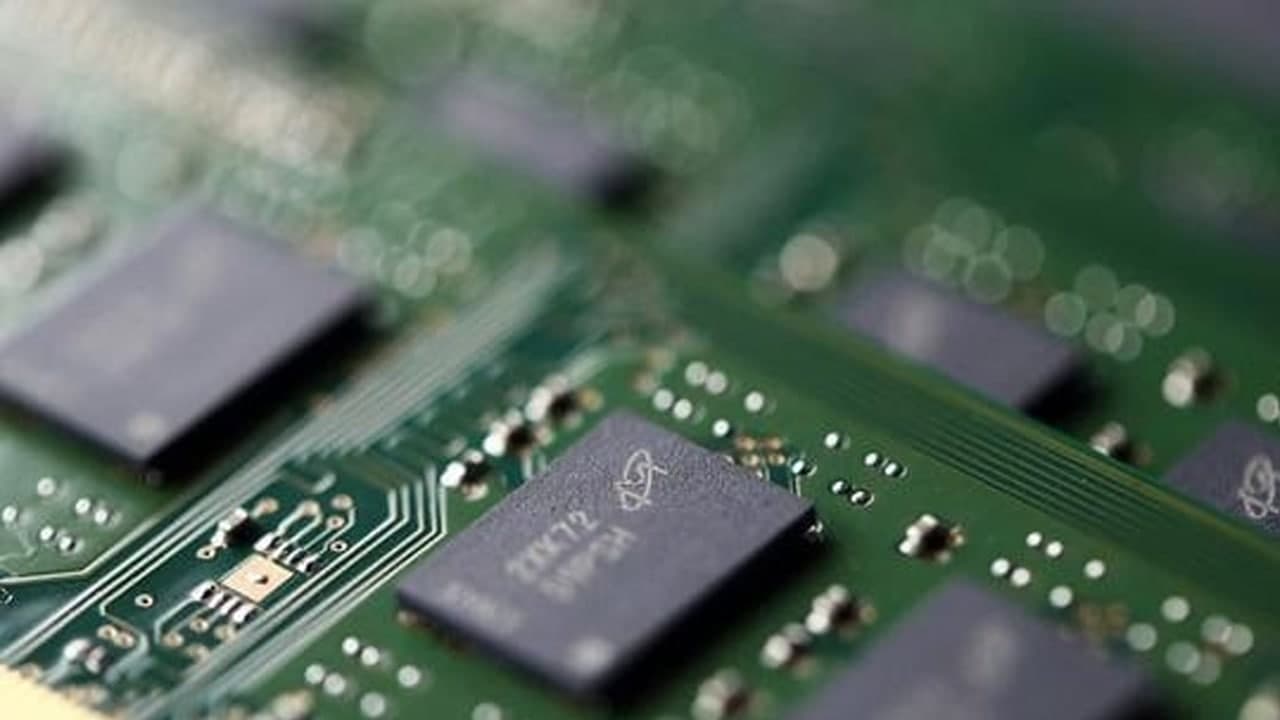

According to the latest report, the OSAT (Semiconductor Assembly and Test) industry is in a state of emergency to secure new equipment. This is because equipment delivery times have more than doubled. The undersupply of semiconductor equipment is spreading in all directions from front to back.

Moreover, OSAT industry insiders and lead times for post-processing equipment used for semiconductor chip assembly and testing have more than tripled on average across all sectors. The lead time was initially 6 months and has now been extended to more than 12 months.

Join tip3x on Telegram

According to a semiconductor industry executive, “equipment lead times for advanced packaging such as fan-out (FO) and mature packaging processes such as wafer-level packaging and flip-chip have nearly doubled.” OSAT has difficulty investing in facilities.”

In particular, lead times for “cut” equipment, ie cut package and test equipment, have become relatively long. According to the survey, the delivery time of Japan’s DISCO equipment, which has a strong position in the semiconductor cutting equipment market, is 1 year and 6 months.

A person in the semiconductor equipment industry said: “DISCO’s main goal is to meet the demand for wafer dicing equipment applicable to the entire production process, so the supply of back-end processing equipment such as package dicing will take a secondary role.”

“Because of the test equipment Also being prioritized by the market, the delivery time of packaging equipment is becoming more delayed.” In terms of test equipment, it is understood that the lead times of Teradyne in the United States and Advantest in Japan have also been extended.

“Because of the test equipment Also being prioritized by the market, the delivery time of packaging equipment is becoming more delayed.” In terms of test equipment, it is understood that the lead times of Teradyne in the United States and Advantest in Japan have also been extended.

Furthermore, there are indications that delays in deliveries of back-end processing equipment will continue until the end of the year. Amkor’s capital spending this year will increase by 22% from last year.

This is a response to market demand and to catch up with the market leader ASE. ASE is also likely to expand investment in equipment to meet growing demand. It is reported that equipment investment in major OSATs in South Korea is expected to nearly triple from last year. It is certain that the competition for devices will be more intense.

Some observers believe that local companies will benefit. Relatively short delivery times have become a competitive advantage compared to foreign products. Due to the inability to obtain equipment from abroad, OSAT is considering home-grown equipment as an alternative.